- Introduction

- Products

- Inquiries

- Customer center

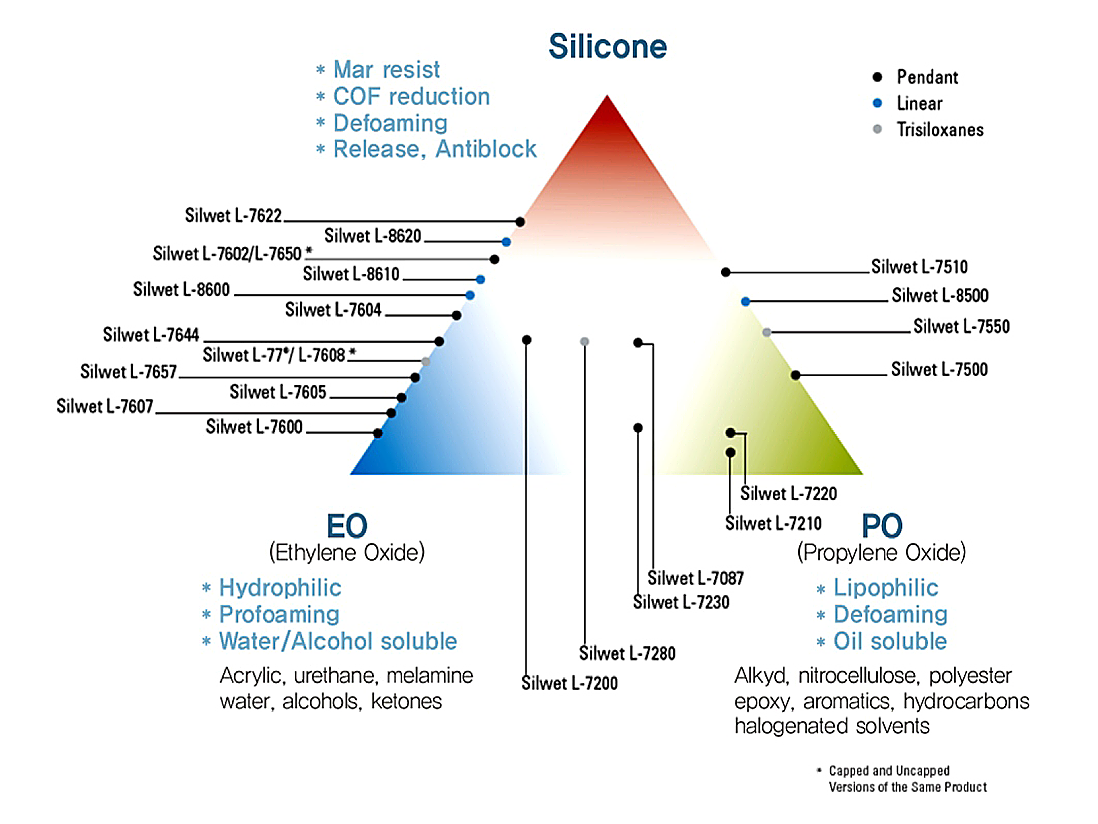

| Structural information | Solubility | Properties & Applications | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Type | Cap(terminal) | Molecular weight | 0.1%Surface tension(mN/m) | EO/POratio | water | Hexane | Water-borne | Solvent-borne / High-solids | UV/EB Curing | Powder |

| Silwet L-77 | Trisiloxane | Me | 600 | 20.5 | All EO | DDD | SDI | Air release, Wetting,Substrate wetting, F/L | Wetting, Substrate wetting,F/L, Air release | F/L, Substrate wetting,Airrelease | |

| Silwet L-7280 | Trisiloxane | H | 600 | 21.5 | 60/40 | DDD | SSD | Air release, Wetting,Substrate wetting, F/L | Substrate wetting,Air release | F/L, Substrate wetting,Air release | |

| Silwet L-7608 | Trisiloxane | H | 600 | 21.4 | All EO | SDD | Ⅲ | F/L, Gloss, Air release | Air release, Wetting,F/L, Gloss, | F/L, Gloss, Wetting,Air release | |

| Silwet L-7001 | Pendent | Me | 20,000 | 28.2 | 40/60 | SSD | Ⅲ | F/L | Wetting, F/L | F/L | |

| Silwet L-7230 | Pendent | H | 29,000 | 32.4 | 40/60 | SSS | Ⅲ | Defoaming | F/L | ||

| Silwet L-7500 | Pendent | Bu | 3,000 | Insoluble | All PO | Ⅲ | SSS | Defoaming | F/L, Wetting, Gloss | F/L, Gloss | |

| Silwet L-7602 | Pendent | Me | 3,000 | 26.6 | All EO | DDD | SⅡ | Slip, Mar resist, F/LAntiblock | Slip, COF reduction,Mar resist | ||

| Silwet L-7604 | Pendent | H | 4,000 | 25.4 | All EO | SSS | Ⅲ | F/L, Watting | F/L | F/L | |

| Silwet L-7605 | Pendent | Me | 6,000 | 30.2 | All EO | SSS | Ⅲ | F/L, Watting, Gloss | F/L, Gloss | F/L | F/L, Gloss |

| Silwet L-7607 | Pendent | Me | 1,000 | 23.4 | All EO | SSS | SⅡ | Substrate wetting,F/L, Watting, | Wetting, Substarte wetting | F/L, Watting | |

| Silwet L-7622 | Pendent | Me | 10,000 | Insoluble | All EO | Ⅲ | SSI | Defoaming, Antiblock,Slip | Defoaming, Antiblock,Slip, COF reduction | Defoaming, COF reduction,Slip, Mar resist | |

| Silwet L-8500 | Linear | H | 2,800 | Insoluble | All PO | Ⅲ | SSS | Defoaming, Slip | F/L, Slip, Mar resist,Gloss retention, Defoaming | COF reduction,Mar resist, Slip | |

| Silwet L-8600 | Linear | H | 2,100 | 25.4 | All EO | SSS | Ⅲ | F/L, Slip | Substrate wetting,Defoaming, F/L, Gloss | F/L, COF reduction, Slip,Mar resist | |

| Silwet L-8610 | Linear | H | 1,700 | 25.7 | All EO | SDI | SⅡ | Defoaming, Antiblock | Defoaming, F/L, Antiblock | ||

| CoatOSil 2816 | Linear | Me | 3,000 | - | EO/PO | SSS | DDD | Slip, F/L, Mar reistane,Compatibility | Slip, F/L, Mar reistane,Compatibility | COF reduction, SlipF/L, Gloss | |

| Hydroxy reactives: | |||||||||||

| CoatOSil 2812 | Linear | Hydroxy | 2,000 | 26.6 | All EO | SDD | Ⅲ | Slip, Mar resist,COF reduction; Defoaming | Defoaming, COF reduction,Slip, Mar resistance | ||

| Acrylic reactives: | |||||||||||

| CoatOSil 3509 | Linear | Acrylic | 2,200 | - | All EO | DDD | SSD | Permanent COF reduction,Slip | |||

| Epoxy reactives: | |||||||||||

| CoatOSil 2810 | Epoxy | Me | 600 | Insoluble | No polyether | Ⅲ | - | Defoaming | Permanent COF reduction,Slip, Flexibility | ||

| Product Types and Uses | concentration | Name | Typical Properties | Thinner | Industrial uses | Characteristic | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Effectiveingredient% | Color | Viscosity(25℃)cSt | Specific gravity(25℃) | Ionicity | Blowing | Defoaming | Workability | Paintable | Additive for food | ||||||||||||

| Aqueous | Non-aqueous | High-temp.*2 | Acid | Alkaline*3 | Quick-effect | Persistence | Storage stability | Dispersible | Dilution stability | ||||||||||||

| Emulsion | Low | SAG 1010 | 14 | Ivory white | 700 | 0.99 | Non-ionic | Water | ○ | ○ | ○ | ○ | ○ | Industrial uses, Wastewater Treatment | |||||||

| Middle | SAG 622 | 20 | Ivory white | 600 | 1.00 | Non-ionic | Water | ○ | ○ | ○ | ○ | △ | High temperature(~100℃), Fiber process, Industrial uses | ||||||||

| SAG 672 | 21 | Ivory white | 1,200 | 1.00 | Non-ionic | Water | ○ | △ | ○ | ○ | ○ | ○ | Fiber Pre-treatment, Dyeing, Industrial uses | ||||||||

| High | SAG 240 | 40 | Ivory white | 700 | 1.00 | Non-ionic | Water | ○ | △ | △ | ○ | - | Good de-foaming at high-temp. | ||||||||

| SAG 535 | 39 | Ivory white | 2,500 | 1.00 | Non-ionic | Water | ○ | ○ | △ | Industrial uses, Wastewater Treatment | |||||||||||

| SAG 638 | 47 | Ivory white | 1,300 | 1.00 | Non-ionic | Water | ○ | △ | ○ | ○ | ○ | △ | Industrial uses, Chemical process, Water Treatment | ||||||||

| TSA 730 | 40 | Ivory white | - | 1.01 | Non-ionic | Water | ○ | ○ | Industrial uses | ||||||||||||

| TSA 770 | 45 | Ivory white | - | 1.01 | Non-ionic | Water | ○ | ○ | ○ | ○ | ○ | Industrial uses, Effective on foaming system | |||||||||

| TSA 775 | 65 | Ivory white | - | 0.99 | Non-ionic | Water | ○ | ○ | ○ | ○ | ○ | ○ | ○ | High temp. Effective on alkaline-bubble solution. | |||||||

| Food process | SAG471 | 100*1 | Translucent white | 2,500 | 0.99 | - | Water, Process solution | ○ | ○ | ○ | Aqueous, Non-aqueous, Food, Industrial uses | ||||||||||

| AF 9000 NE | 100 | Gray | <2,500 | 1.01 | - | Aliphatic solvent, Aromatic solvent,Process solution | ○ | △ | ○ | ○ | ○ | ○ | ○ | Food, Non-aqueous(Oil,solvent) | |||||||

| AF 9020 | 20 | Ivory white | <3,000 | 1.01 | Non-ionic | Water | ○ | ○ | ○ | ○ | ○ | ○ | Food process, Industrial uses(Acid, Alkaline) | ||||||||

| AF 9030 | 30 | Ivory white | 5,000 | 1.01 | Non-ionic | Water | ○ | ○ | ○ | ○ | ○ | Food process, Industrial uses | |||||||||

| TSA 737 | 31*1 | Ivory white | - | 1.01 | Non-ionic | Water | ○ | ○ | ○ | Food process | |||||||||||

| TSA 737F | 30*1 | Ivory white | - | 1.01 | Non-ionic | Water | ○ | ○ | ○ | Food process | |||||||||||

| TSA 750 | 100*1 | Translucent light ash | 600 | 1.00 | - | Aliphatic solvent, Aromatic solvent | ○ | ○ | ○ | ○ | Aqueous, Non-aqueous, Food | ||||||||||

| TSA 750S | 100*1 | Translucent light ash | 1,000 | 1.01 | - | ○ | ○ | ○ | ○ | Aqueous, Non-aqueous, Food | |||||||||||

| THF450 series | 100 | Transparency | 105-1,000 | 0.97 | - | Aliphatic solvent, Aromatic solvent | ○ | △ | ○ | ○ | Dimethyl silicone oil, Food | ||||||||||

| FiberProcess | SagTex DSA | 20 | Ivory white | 1,000 | 1.00 | Non-ionic | Water | ○ | △ | ○ | ○ | ○ | Fiber process( ), Refing, Desizing, Industrial uses. | ||||||||

| SagTex PhD | 45 | Ivory white | 2,000 | 1.00 | Non-ionic | Cold water | ○ | △ | ○ | ○ | ○ | Fiber process | |||||||||

| SagTex JSA | 100 | Ivory white | 250 | 1.00 | - | Process solution | ○ | ○ | ○ | ○ | Jet scour, Translucent | ||||||||||

| Natural gasRecovery | SAG 7133 | 10 | Ivory white | 600 | 1.00 | Non-ionic | Water | ○ | △ | △ | ○ | ○ | ○ | Natural gas Recovery(Amine, Glycol dehydration) | |||||||

| SAG 220 | 20 | Ivory white | 600 | 1.00 | Non-ionic | water | ○ | △ | △ | ○ | ○ | ||||||||||

| SAG 47 | 100+1 | Translucent white | 2,500 | 0.99 | - | Process solution, Hydrocarbon | ○ | ○ | ○ | Natural gas Recovery | |||||||||||

| Natural gasRecovery | TSA 720 | 5 | Transparency | 2 | 0.87 | - | Aliphatic solvent, Aromatic solvent | ○ | ○ | ○ | Toluene of Dimethyl silicone oil | ||||||||||

| YSA 02 | 20 | Transparency | 1,000 | 0.82 | - | ○ | ○ | ○ | Mineral spirit of High MW Dimethyl silicone | ||||||||||||

| Oil compound | SAG 1000AP | 100 | Translucent white | 1,300 | 0.99 | - | Aliphatic solvent, Aromatic solventProcess solution | ○ | ○ | ○ | Industrial uses, Petrochemitry | ||||||||||

| Self-emulsification | SAG 689 | 100 | Ivory white | 5,000 | 1.00 | Non-ionic | Cold water | ○ | △ | ○ | ○ | ○ | Fiber, Industrial uses | ||||||||

| YSA 6403 | 100 | Light brown | 500 | 1.03 | Non-ionic | Cold water | ○ | △ | ○ | ○ | ○ | ○ | water-soluble, Paintable | ||||||||

| YSA 6406 | 100 | Light brown | 2,000 | 1.01 | Non-ionic | Cold water | ○ | ○ | ○ | Effective on foaming system | |||||||||||

| TSA 780 | 100 | Light brown | 1,000 | 1.02 | Non-ionic | Cold water | ○ | ○ | ○ | ○ | ○ | Acid Aqueous system, Fiber, Industrial uses | |||||||||

| oil | TSF 451 series | 100 | Transparency | 10-50만 | 0.94-0.98 | - | Aliphatic solvent, Aromatic solvent | ○ | △ | ○ | Dimethyl silicone oil, General | ||||||||||

| FF 160 | 100 | Transparency | 20,000 | 1.12 | - | Toluene, Acetone,Low-MW Ester/Ether | ○ | ○ | ○ | ○ | Separate crude petroleum | ||||||||||

| FF 170 | 100 | Transparency | 4,000 | 1.13 | - | ○ | ○ | ○ | ○ | ||||||||||||

| SAG TP-317 | 9 | Lemon yellow | 480 | 1.03 | - | Alcohol or Aromatic solvent | ○ | ○ | Diesel | ||||||||||||

| SAG TP-325 | 9 | Lemon yellow | 400 | 1.03 | - | ○ | ○ | ||||||||||||||